Testified by their high global standing and customer reputation, it’s safe to say that Dolmar are among the industry’s most trusted brands when it comes to outdoor power tools and reliability in products. However, just like any other brand’s tools, these are products that are constantly subjected to harsh and humid external conditions such as heat, dust, snow and other elements. While it’s expected that you may have to deal with occasional problems or breakdowns from time to time, it’s often easy enough to fix these issues at your own garage without having to haul the machine over to a servicing center.

Always practice safety first

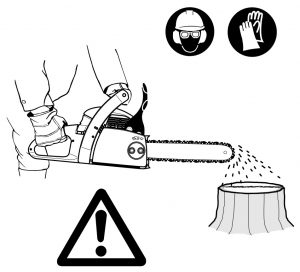

It’s important to always bear in mind that these are extremely dangerous power tools with fast moving parts that can cause serious injury or damage if not used properly. Ensure that you go through all the safety instructions and learn all the safety signs and decals before attempting to use the tool.

- Ensure you always wear the right protective clothing, boots, gloves and eye protection before using the chainsaw for you own personal safety.

- Learn all the operating instructions and signs, control switches of the chainsaw before attempting to operate it.

- If you’re unable to fix a mechanical fault or are not comfortable working with power tools, do not hesitate to take the tool to an authorized service centre.

- Gasoline powered chainsaws can run quite loud in the decibel range and it is important you wear hearing protection to ensure that your ears do not dace chronic damage

- Do not attempt to operate the tool in unsafe, particularly dusty or damp conditions that may pose a risk to your safety or the safety of those around you.

- Ensure that there are no collateral substances prone to damage in the vicinity at all angles from the tree you are going to fell as it is often unpredictable how a tree will fall.

- Do not use the power tool if you are tired, sleepy or especially if you are intoxicated as this can lower your reaction speed and decrease your capability to swiftly deal with any dangers.

- Using a chainsaw can be physically demanding so ensure that you are in good physical condition before attempting to use the machine.

- It’s important that you make sure there is a fire extinguisher available nearby when using the chainsaw.

- Only carry out refueling in places where it is safe to do so, do not handle fuel in closed spaces or areas with bad ventilation. Fumes from gasoline can be hazardous to health.

- It’s important that you regularly service and lubricate the chainsaw to ensure not just longevity of the tool, but also safer operation.

- Ensure that you start the unit when it is in a safe position on the floor, do not attempt to start the chainsaw while handling it standing up or sitting down.

- Immediately clean up any fuel or oil that you may happen to spill while lubricating the chainsaw.

- Do not use very old fuel or oil as they can change in characteristics over time.

- Ensure that there are no animals in the area when using your chainsaw as they can pose a distraction and safety hazard.

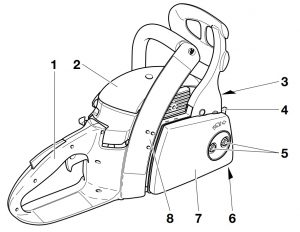

Identifying the various parts of the chainsa

1. Handle of the unit

2. Filter covering

3. Muffler piece

4. Spike bar stoppage

5. Retaining rut

6. Chain catcher safety mechanism

7. Sprocket guarding rail

8. Adjustment screws for the main carburetor

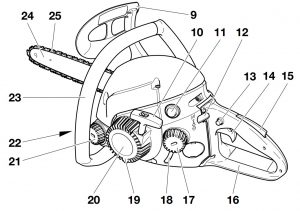

9. Safety guard for hands

10. Starter release grip

11. Fuel fill pump

12. Combination of the power switches start, stop, switch, choke etc

13. Halfway throttle stop knob

14. Throttle lever control

15. Safety locking mechanism release switch

16. Hand guard for rear end

17. Fuel tank cap

18. Fill level window spotter for fuel tank

19. Staring assembly with in-built fan housing

20. Identification numbering and plate

21. Oil tank stopper cap

22. Fill level window spotter for oil

23. Tubular handle

24. Guiding bar

25. Chain

Dolmar troubleshooting tables

Dolmar chainsaws are known as very good quality equipment that when properly maintained rarely brakes. Most common troubleshooting issues and its solutions can be found in the table below

Table number 1- Dalmar most common troubleshooting applicable for all Dalmar models

| PROBLEM | POSSIBLE CAUSE | SOLUTON |

| Chainsaw not rotating | Clutch pads may have dulled and worn out | Install new clutch pads in place of the older ones |

| Chain brake might be activated | Disengage the chain brake | |

| Engine starts with difficulty | Ignition spark might not be happening | Spark gap needs to be recaliberated |

| Spark plug might have become work out or old | Replace the older spark plug with a new piece | |

| Carburetor might have grown clogged or become obstructed | Clean out the inside of the carburetor thoroughly and tune it again | |

| The compression system may be defective | Inspect the cylinder rings and the radial shaft packings | |

| Fuel might need to be replaced | Drain out the old gas and refuel with fresh gasoline | |

| Engine stalling after starting | Carburetor might have grown clogged or become obstructed | Clean out the inside of the carburetor thoroughly and tune it again |

| Fuel might need to be replaced | Drain out the old gas and refuel with fresh gasoline | |

| Fuel line may be jammed or defective | Inspect the suction head of the carburetor and clean out the fuel line | |

| Rough operation for the chain | Carburetor might have grown clogged or become obstructed | Clean out the inside of the carburetor thoroughly and tune it again |

| Chain tension might be too low | Increase the tension of the chain by tightening it | |

| Fuel might need to be replaced | Drain out the old gas and refuel with fresh gasoline |

Table number 2- maintenance schedule applicable for all Dolmar models

| Time period | Maintenance required |

| Daily | Clean the exterior and remove any residual saw dust that may have accumulated |

| Ensure that the chain brake is in proper working condition | |

| Clean out the air filter and its various components including the filter element | |

| Turn the chain bar over to balance wear and tear | |

| Lubricate the blade and inspect oiler | |

| Check the starter cord for any possible damage or wear | |

| Test the engine stop switch | |

| Ensure that the main chain is well tensed and increase tension if necessary | |

| Weekly | Check the blade sharpness and sharpen with file if necessary |

| Lubricate the clutch drum’s bearing and the inner parts | |

| Look for burrs on the end of the bar and file them off if required | |

| Measure the spark gap and recalibrate if required | |

| Inspect condition of the starter spring and recoil spring | |

| Ensure that the air filter’s screen and the cooling fins are clean and free of sawdust or debris | |

| Monthly | Check for wear at the brake band and guide bar |

| Ensure the clutch centre and the spring is free of wear | |

| Clean the exterior of the clutch pads and screens | |

| Change the old fuel filter with a new one | |

| Clean out the fuel line and the internal chamber | |

| Look for loose connections in the cabling | |

| 3 Months | Replace the suction head with a new one |

| Clean out the fuel line and the internal chamber |

Judging the fall of the tree properly

Its absolutely critical that you practice the right cutting technique when felling trees or cutting lumbar that has been secured to a surface as it can improve your workflow and avoid mistakes that lead to dangerous situations, such as kickback.

Working with secured lumbar Remember not to lean too far forward over the workbench when cutting a secure piece of lumbar, and ensure that all fastening have been tightly fitted to hold the tree properly in place while you work on the piece. If the lumbar tends to come loose again and again, you might need to check the fastenings or use a different work bench. While preforming crosscuts the spike bar needs to be applied to the wood that it cuts. Press the crosscut firmly into the tree while cutting and avoid using an irregular to and fro motion that goes too far beyond the grain of the wood. For longitudinal cuts, more experience is required and it is highly recommended that these cuts be carried out by trained professionals as the risk of kickback is significantly higher.

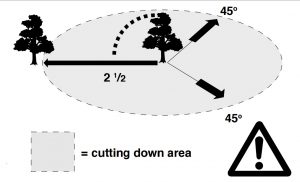

Working with freestanding trees While attempting to cut freestanding trees is of primary importance that you first asses the surrounding area and ensure that there is ample space for the tree to fall. It is equally important that you ensure there are not houses, people, animals or other structural elements that may be damaged or pose a risk if the tree happens to fall on them. Remember it is difficult to always predict the falling trajectory that the top of the tree will trace as this can vary based on a number of conditions such as wind speed, branch density, incline of the ground, density of the soil and more.

Only people involved in the operation must be in the working vicinity of the tree and you must ensure that all involved workers have enough room to withdraw from the falling tree properly. The length of the tree along the floor must be traced before you begin cutting. Also make sure that you mark 45 degree angled trajectories at the three sides around a tree, as these are the three most likely directions the tree can fall (if it doesn’t fall in the path originally intended). However, it is recommended that the entire surrounding radius of the tree is free of debris while performing the cut.

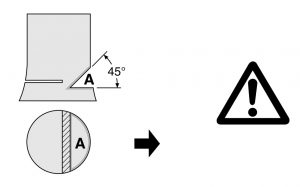

While cutting, ensure that you begin by properly carrying out all the necessary cuts required to ensure the tree can fall freely. Begin by cutting the roots and start with the strongest root. It is recommended that you preform a horizontal and then a vertical cut to ensure proper destressing of the trunk. While cutting the notch, ensure that you carry out all the required measurements before you begin the cut. Do not attempt to cut the notch prior to measuring as getting the angle wrong may drastically change the way the tree falls. Mark a 45 degree angle wedge section (A) for the tree’s trunk to be cut in and ensure that the tree is still secured during this process.

Operating the chainsaw

Ensure that the chainsaw is well lubricated and that the clutch pads are in good condition before you attempt to start the chainsaw. Now insert your foot into the free loop within the rear handle and with one hand firmly grasping the guide bar, pull the starter rope towards you in a brisk motion. Do not let the rope fall back to the unit under its own tension, gradually slide it back into place. If the engine does not start, repeat the motion again until the motor springs into life. Always start the chainsaw with the unit on the floor.

It is safe to pick up and handle the chainsaw after you have properly started the engine. Use the hand trigger to begin turning the chain blade. Never run the chainsaw with the chain brake activated – remember that the chain brake is in position to turn off the rotation of the chain if the kick back is sufficiently strong enough.

Proper maintenance of the chainsaw

Lubrication of the chainsaw is of crucial importance as this ensure that the chain is rotating properly and that all components of the machine are working properly. It is important that you regularly check the lubrication of the chain blade, especially before each use. You can check the lubrication of the chain blade by running the chainsaw over a stump, around 15 cm from the wood. If there is sufficient lubrication, the oil will trace a light path along the trunk and the ground.

Remember that it is normal for oil to drip from the chain blade after you turn off the engine. This is not a defect and is expected. Also ensure that you regularly check the condition of the carburetor as well as the spark plug. A faulty spark plug will make it harder to start the motor and you may need to replace this every 6 months to one year as specified in the instruction manual.